The air braking system on trains

In winter, braking on trains is another story!

Cold weather and snow can impact train braking systems. For your safety, the train is designed to brake if any issues are detected.

How do the brakes work?

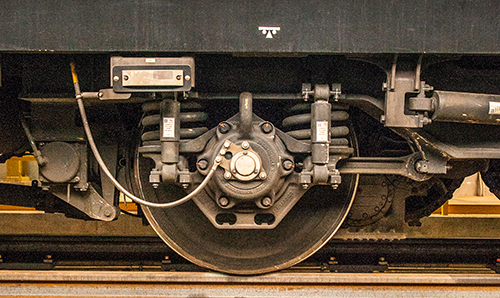

Exo trains are equipped with air brake systems that use compressed air to apply the brake shoes to the wheels and to the brake discs located on the axles.

What happens when there’s a problem?

- Our trains are equipped with an integrated fail-safe system. If the compressed air and braking systems encounter any problems, the brakes are applied to ensure your safety.

- In most cases, the team on board is able to remedy the situation. If not, a technician will be dispatched on site. The length of time necessary for repairs depends on the severity of the situation and how far the technician has to travel to reach the train.

Problems? Solutions!

In order to act rapidly, we deploy a high number of technicians in winter.

We are also in the process of upgrading various components on our MR-90 railcars to prevent recurring problems.

Problem

Moisture must not get into the braking system (connections, valves, tanks) because if a component freezes, the brakes will be applied.

Solution

We’re replacing the original, 23-year-old air dryers with new ones in order to adequately remove moisture in the system.

Problem

During snowstorms or rapid changes in temperature, the valves located beneath the railcars may be hit by all sorts of debris (ice, snow), which creates an imbalance in the system.

Solution

We’re installing valve deflectors and protectors beneath the railcars to minimize impacts.

Problem

In winter, pressure sensors and valves can freeze.

Solution

We’re adding heating elements to certain critical air system components beneath the railcars, and relocating other braking components to compartments inside the railcars.

Did you know?

To ensure the electrical braking panels operate correctly, we are replacing certain contacts with new ones on critical components.

Read on to learn about exo’s initiatives to improve the door, wheel and propulsion systems.